Construction of a house from rounded logs is a technology for assembling a log cabin. Stages of building a house from a bar Stages of building a house from a bar with communications

House building is a responsible task that must be entrusted to professionals. But it is useful for the future owner to know what are the main stages of building a private house and the sequence of actions. This is necessary for an adequate assessment of the final estimate and deadlines, for monitoring the progress of work.

The construction stages are identical for houses made of logs, profiled and glued beams.

We propose to consider the stages of building a log house using the example of our house project and its implementation.

1. Design

You can download « » in pdf format and get acquainted with the layouts.

Despite the fact that today the design of wooden houses most often comes down to choosing a refined and balanced option from the contractor's catalog, any project needs to be adapted. It is necessary to determine the layout and purpose of the premises and, if necessary, make changes to the floor plan.

An important stage of adaptation is the choice of foundation. In order to determine its type and make accurate calculations, it is advisable to conduct preliminary geodetic monitoring of the site, since some foundation parameters depend on the depth of groundwater, soil type, and the presence of quicksand.

In this example, the most suitable foundation, due to the large difference in the area, was chosen - a pile screw foundation. On the front part, the length of the piles is more than 9 meters. Pile 133 mm., pile wall thickness 6 mm;

2. Site preparation for development

After drawing up and approval of the adapted project, a house kit is made from rounded logs. While it is being made, you need to prepare construction site. Our experts will carry out geodetic binding and marking of axes, will deliver the necessary materials, tools and equipment to the construction site.

If autonomous communications are planned at the facility (well, septic tank, gas tank), we recommend planning them in advance or at least approving their location. Otherwise, situations are not ruled out when the equipment is subsequently mounted for technical reasons in a completely different place, and the inputs to the house are already arranged in accordance with the original plans.

It is important to organize conditions for builders (change houses, hygiene, food), take care of fire safety, equip a place for shipping materials and storing garbage.

3. Foundation and communications

Installation of modern pile foundations is carried out quickly, with the involvement of special equipment. According to the technology, sand-concrete mixture is poured into the installed piles and the heads are welded. Next comes the welding. The upper points of the pipes are aligned, additional stiffeners are welded to them, they are closed with plugs and cuts are made.

On the finished metal frame, a 200x200 mm beam is arranged along the top of the pile head, which is needed for uniform distribution of the bearing load and additional reliability of the geometry. At the end of the stage, in the places provided for by the project, communication pipes are laid and brought to the level of the future floor of the first floor.

4. Domokomplekt

The finished factory kit is brought to the construction site sequentially folded and numbered. According to the prefabricated drawings, referring to the markings, the house kit made of rounded logs is mounted on the foundation. At the floor level of all floors and the attic, logs are laid - the bearing horizontal support of the floors and the roof.

5. Rafters and roofing

When the entire set of logs is installed, the roof frame is equipped along the upper lags - a truss system from a 50x200 mm board, on sliding supports in 0.58 mm increments. and the possibility of insulation in 200 mm. Finishing roofing material is placed on the rafters. You can immediately mount the finish roof, as is done in our example.

6. Wood processing and shrinkage

Important stage of construction country house- house set shrinkage. The rounded log shrinks 6-9% In order for this process to occur correctly and evenly, it is necessary to carry out not complicated, but very important measures to protect the wood and the ends of the assembled house.

In all openings (doors, windows, arches), one or two logs not taken out are left - dressing. Vertical bearing supports are equipped with compensators - adjustable supports, usually metal. They are placed in the gaps in the upper, supporting part of the pillars.

Shrinkage is a long process. So that the wood does not darken and damp under natural climatic conditions, all logs and beams must be carefully processed.

All ends of the house must be covered with protective compounds from cracking and the outer walls of the house must be covered with antiseptic coatings. When contacting our company, we will recommend, explain and show how different protective compounds differ from each other and which ones should be used correctly.

As a rule, such processing is combined with fire protection.

7. Closing the circuit

After completing the main, most significant shrinkage, you can begin to close the outer contour. This stage of building a log house consists of the following sub-stages:

- lining and insulation of the foundation, the device in it of products (ventilation openings);

- arrangement and insulation of the blind area around the foundation;

- log house insulation (caulking, insulation of intervent spaces);

- arrangement of window and door openings, installation of windows and entrance doors;

- roof filing from the outside, roof insulation, floor insulation, attic ventilation, engineering wiring

8. Floor, ceiling and partitions after 6 months of shrinkage

In the closed circuit of the house, it is already possible to start filing ceilings, laying the floor (at least a rough one). If the project provides for additional partitions, the frames for them are usually erected immediately on the subfloor.

When the internal volumes are obtained and all rooms are delimited, the location and dimensions of the interior and floor openings are specified. At the same time, ventilation shafts are erected, stoves and fireplaces, chimneys are arranged.

If initially the house was covered with a temporary roof for shrinkage, after this stage of building a private house, you can proceed to the final roof and equip the roof with snow retainers and a drainage system.

9. Wiring communications

Before proceeding with the interior decoration, all the necessary communications are installed around the house: they arrange boiler rooms and boiler rooms, draw electricity, provide heating, water supply, and sewerage.

Before proceeding with the interior decoration, all the necessary communications are installed around the house: they arrange boiler rooms and boiler rooms, draw electricity, provide heating, water supply, and sewerage.

At the stage of finishing, only the final user equipment is left, which can deteriorate during repair work - lamps, switches, sockets, radiators.

10. Joinery and finishing

At the initial stage of finishing work, immediately after finishing floors, doors, stairs, window sills and slopes are installed, free doorways and arches are cashed. If it is necessary according to the project, the carpentry and log walls are tinted.

The same, if necessary, is done outside. Facade finishing (painting logs, platbands, decorative elements, veranda and balcony railings) can be done in parallel with the interior, before or after. Further finishing depends only on the budget, the imagination of the owners, the availability of an interior design project.

A common practice at the finishing stage is the creation of small forms from log trimmings (for example, from removed dressings) for a garden, veranda or even an interior.

The Ruklad company wishes all future homeowners to safely wait for this pleasant final stage of the construction of a country house !

11. Video of the construction of the house "Flagman"

A house made of logs is a more progressive analogue of the traditional Russian log house - a hut that our ancestors built. Although the construction of a house from chopped logs has not lost its relevance.

Paying tribute to tradition modern technologies allow you to get construction material- rounded log, having the same diameter along the entire length, with clearly defined parameters of longitudinal grooves and seats (bowls).

Visually, the modern log house has also undergone changes and began to look much smoother and neater. The operational characteristics of the log itself have also changed. As a result of processing, it has become more stable, resistant to torsion, and most importantly, unlike chopped logs, rounding has no taper. Stable geometry increases the speed of assembly of the house and its quality.

Advantages and disadvantages of log houses

It is possible to single out both advantages and disadvantages, most of which are subjective or depend on the source material or the quality of processing.

Advantages of log houses

- predominantly natural materials are used. Usually, the finish is chosen to match the house from natural materials;

- excellent natural ventilation, due to which there are no prerequisites for the appearance of condensate, dampness, the development of strokes and mold;

- there is a unique spirit of natural wood, which has a positive effect on human health; The material was prepared for the site www.site

- warm in winter and cool in summer. Due to the tight fit of the logs and the low thermal conductivity of the wood itself, a house built from a log of large diameter does not need additional insulation and air conditioning;

- attractive facade, exterior and interior.

In addition, a log house is a strong, reliable, stable structure, the construction of which takes from 5 to 30 days, depending on the project. At the same time, the construction of a house from a log is considered one of the economically viable projects in private construction, with an optimal combination of price, quality and construction time.

Cons of log houses

Disadvantages should be considered first of all in order to take measures to eliminate them and avoid possible errors.

- shrinkage. The main disadvantage of a house made of logs. Note that wood construction is always associated with shrinkage of buildings, this is due to the characteristics of the wood itself. But, a six-month break in work for the most active shrinkage, the choice of dry material, the use of jacks, strengthening the junction of logs, etc. nuances will reduce the shrinkage of the log. An indicator of 8-10% is considered optimal;

- combustibility. Wood burns - that's a fact. But it does not belong to easily flammable materials, and the probability of its spontaneous ignition (for example, from electrical wiring) is no higher than in other houses. But a wooden house is easier to put out, and the smoke emitted during the combustion process is not as toxic as that of heaters used to insulate stone houses;

- cracking. The appearance of cracks is also a natural process for wood. You can minimize their appearance by buying a dry log and putting the house into operation correctly, in particular, the correct mode of heat supply during the onset of cold weather;

- care. A wooden house is constantly in need of care. Periodically, it is necessary to caulk the cracks and cover the log to protect against external factors. But, any private house needs care. Taking care of your own home can hardly be considered a serious disadvantage.

When is the best time to build a log house?

You can choose the start of construction based on your own capabilities. Any time, with the exception of autumn, allows you to perform construction works. However, the most preferred time of the year to start assembling a log house is the end of winter. This is due to such factors:

- winter forest is considered the best for building houses;

- in the winter season there is no precipitation, and it is easier to protect a log from snow than from rain;

- since the house is being built quickly, the developer has spring for the gradual drying of the wood, and summer for the most active phase of shrinkage, and in the fall it will be possible to install a permanent roof.

Round log house project

Any construction must begin with the development of a project, and a project for a residential building made of logs needs to be approved by various authorities.

What you need to design a log house:

- order the development of an individual project, develop a project independently using computer programs, download a standard project and modify it taking into account the peculiarities of the place and operating conditions (geodetic surveys will need to be carried out);

- calculate the parameters of the future home: total area, usable area, number of living rooms, their purpose, take into account the special requirements of residents (for example, pensioners or people with disabilities), take into account all wishes, because the house is being built for the whole family and will be operated by several generations ;

- think over the truss system and choose the roofing material. It should be heavy enough to create pressure on the walls and prevent gaps between the logs;

- take care of the protection of the south side of the house. As you know, it is she who is most susceptible to rapid shrinkage due to direct sunlight. Therefore, most projects contain a veranda or covered terrace along the south side of the log home;

- make a log - a document that will allow you to order a house kit made of rounded logs for self-assembly or simplify the fitting of logs when using moldings.

What timber is better to build a house from?

A log house will only be able to reveal all its features when it is made of high-quality building material.

How to choose ? For the right choice, you need to know the technical characteristics and parameters of the log:

- log diameter. For the construction of a residential building for year-round operation, only logs with a large diameter are suitable - from 240 to 260 mm or more. Thin logs can also be used if the house is located in a region with a mild climate or additional insulation is expected.

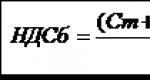

The calculation of the actual value of the heat resistance of the walls is carried out according to the formula:

After calculation, the obtained value is compared with the normative value for a particular region of residence (reference data).

After calculation, the obtained value is compared with the normative value for a particular region of residence (reference data).

For example, for Moscow and the Moscow region R = 3.0 (m²*°С)/W.

At the same time, it should be noted that according to SNiP II-3-79, the value of the thermal conductivity coefficient (λ) depends on the humidity in the region.

- logging period. A log harvested in the winter season is drier, because. in winter, the process of sap flow in the trunk slows down greatly. And the drier the log, the fewer cracks there will be on the constructed walls. The best forest in Karelia, Arkhangelsk and Angarsk regions.

- breed. The rounded log is made from coniferous wood - a pine or a fur-tree. However, for the lower crown, you should choose a denser wood, such as larch;

- log color. The hue should be uniform, corresponding to the breed, without blue;

- foreign inclusions. The presence of knots, resin pockets, mechanical damage or biological activity in a quality log is not allowed;

- cracks. Allowed, but their depth cannot exceed a third of the diameter;

- geometry. The log should be even, not twisted, with neatly sawn longitudinal grooves and bowls;

- surface quality. The surface must be even and smooth. The presence of burrs and roughness indicates poor sharpening of the cutting tool and will require grinding the wall after installation;

- compensation cut. Not every manufacturer makes propyl. However, its presence can reduce internal stress in the barrel and reduce the likelihood of cracks;

- profile. There are two types of profile - lunar and Finnish. The first - more traditional, allows you to make a quick installation. The second one has shoulders (shoulders) - protrusions on the ridge that protect the junction of the logs from the appearance of cracks during shrinkage. In addition, the thermal groove with such a profile is larger, which leads to an increase in the number of crowns during the construction of the wall, but makes it warmer, because. the width of the wall at the junction becomes larger. For example, a log with a diameter of 220 mm. with a lunar profile, has a thermal groove 110 mm thick, and with a Finnish one - 140 mm;

- the ratio of the diameter of the core and the total log. It should be 75% of the cut;

- log processing degree. Antiseptic logs are a prerequisite;

- storage conditions. The log is stored in stacks, without packaging, in a place with good ventilation, protected from moisture and direct sunlight.

The technology of building a house from rounded logs

Do-it-yourself step-by-step instructions for assembling a log house or for understanding the construction process when attracting private craftsmen, a contractor (turnkey construction). All stages of construction with explanations and photos.

The foundation for a house made of logs

The strength and stability of the house, as well as the uniformity of shrinkage, is determined at the stage of laying the foundation.

The cost of the foundation in the construction of stone houses is up to a third of the construction budget. Wooden houses are much lighter, therefore, the requirements for the foundation are more loyal.

For a house made of rounded logs, it is better to fill in a tape or install a columnar (pile) foundation. The type and depth of installation depends on the characteristics of the soil: type, freezing depth, groundwater level, relief.

The recommended height of the foundation (basement) is 40-50 cm from the ground (to protect the logs of the lower crown from snow and splashes of rainwater). For the same purpose, a visor (low tide) is made along the upper edge of the base, reflecting splashes.

Before starting work, the foundation must be checked with a level, because. laying logs requires a perfectly flat surface.

After the construction of the walls, the foundation will be covered with a low tide to protect it from water.

Foundation waterproofing

Due to the fact that wood and concrete have different thermal conductivity, the tree of the lower crown needs to be protected from moisture and condensation. To do this, the foundation must be isolated. As a waterproofing material, roofing material is used, laid in two layers, glass isol (in one layer). The material should lie flat on the surface of the foundation and protrude beyond its edges by 30-50 mm.

Laying the crowns of the house from rounded logs

Crown- this is one row (belt) of logs laid around the perimeter of the building. Assembled and fastened crowns form the walls of the house.

When building a house from rounded logs, they use different kind crowns:

- crown crown- this is the first row of logs that are laid on the foundation (also called - lower, first, mortgage);

- bottom trim- the second (lag) crown, which allows you to form a draft floor in the house from rounded logs, as well as an interfloor overlap;

- ordinary crowns- other rows (wall);

- window- are shortened logs (shorty) from which window openings are made;

- windowsill- logs laid from the lower crown to the window;

- overwindows- logs laid on top of window crowns. The first crown crown is the closing crown.

- top harness- the basis for the installation of the roof truss system.

Regardless of the type of crown, each log must be coated with an antiseptic before laying. This will protect it from all sides, incl. at the junction. The treated log will be protected primarily from biological activity and will prevent decay.

1. The first crown of the house (salary or lower)

For laying the first row, denser logs are used, as a rule, from larch. Hardwoods are more difficult to process, so they are less common on the market. But, aspen and oak are perfect. Before proceeding with laying, you need to make a longitudinal cut on the log. Unlike the grooves that are on every log, a cut is needed in order for the log to lie on the foundation with a maximum area. This will evenly distribute the load and make the frame more stable.

Logs of the mortgage crown are treated with antiseptics in 2-3 layers.

After laying the first crown, the laying diagonal is checked, the discrepancy should not exceed 5 mm.

Note. The log of the mortgage crown is not attached to the foundation.

2. Second crown (lag) - lower harness

The floor in the house from rounded logs is formed directly in the process of laying crowns. Logs can also be installed in the first crown, but the tie-in reduces their strength. Therefore, the logs, according to new technologies, are installed in the second crown on the support beams.

How to cut floor beams (logs) in a log house:

- the beam is fixed with a pin made of reinforcement, which is inserted into a pre-drilled hole or using a metal support for the beams (log holder);

- the beam is impregnated with an antiseptic and flame retardants;

- places for the installation of beams are outlined;

- a groove is cut inside the log (using a chainsaw). The depth of the groove is chosen so that the support beam fits firmly into the log;

- installed in a prepared place;

- after the erection of ordinary walls, logs will be laid on the beam in increments of 600-700 mm.

The technology of cutting floor beams into a log

How to install the floor log on the support beam

Logs for the floor rest on a beam attached to the foundation

3. Ordinary crowns

Ordinary crowns are laid similarly to the first, with mandatory check horizontal, vertical and diagonal. A roll insulation is placed between the crowns, as a rule, a jute cloth.

Note. The vertical check is performed from the inside of the wall.

The figure shows how to lay a rounded log correctly.

Methods for joining logs in a log house

Regardless of how the type of the crown fits, special attention is paid to the formation of longitudinal, angular and T-shaped joints.

For chopped logs, three cutting technologies “into a bowl” are used: Russian, Canadian and Norwegian cutting of a log, as well as cutting “in a paw”.

1. Longitudinal connection of the log (along the length)

To lengthen the log, a dovetail joint is used, since it allows you to create the most durable and reliable butt joint.

2. Corner connection of logs

Planting bowls are usually made in a factory way to form a “into a bowl” connection in half a tree.

When building a house from molded rounded logs, three types of corner connection with the remainder are used:

Cutting "in the bowl" or "in the oblo"

In this case, the connection has a residue, looks nice, but increases the consumption of wood.

The technology for mounting rounded logs in this way has three varieties:

- with oval crest. There is an oval-shaped comb in the deepening of the bowl;

- half a tree. A seat is cut in half the diameter of the upper and lower logs;

- in fat tail. In the deepening of the bowl of one log there is a special recess, and in the bowl of the other log there is an additional protrusion.

Types of cutting corners from logs "in clasp", connection with a ledge

Types of cutting corners from logs "in clasp", connection with a ledge

Cutting "in okhlop"

This method of fastening is distinguished by cutting the bowl in the lower part of the log, as a result, the upper log, as it were, slams the lower crown, which is why it was called - in an okhlop.

Cutting a corner from logs "in okhryap", a corner knot with a residue

Cutting a corner from logs "in okhryap", a corner knot with a residue

Cutting "in okhrjap"

With the method of cutting corners "in ochryapka", the log has additional recesses in the seats.

Much less often, a residue-free connection method is used - "in the paw". In turn, it has three options: a simple (straight) paw, a paw with a cut and an oblique paw with a cut.

3. T-shaped connection of logs

It is carried out by means of a “dovetail” connection (residue-free method) or “in a bowl in half a tree” (connection with the remainder).

It is carried out by means of a “dovetail” connection (residue-free method) or “in a bowl in half a tree” (connection with the remainder).

Log dowel

To stiffen the wall, the logs are fastened together using dowels - wooden fasteners. Often dowels are cut from the remains of a log, but it is more correct to use special fasteners for this, which satisfies the following parameters:

- made of hardwood (for example, birch). Such a dowel is more durable than coniferous;

- the diameter of the dowel (usually 25 mm) exceeds the diameter of the hole by 2-3 mm;

- has a square shape (provides uniform shrinkage);

- humidity corresponds to the moisture content of the log.

Note. Metal pins or pins made of corrugated reinforcement are not suitable for mounting. Iron pins tend to rust, and on corrugated fittings, the log will hang during shrinkage and there will be cracks.

How to install dowels correctly:

- the log installed in place is temporarily fixed with nails. In this way, the displacement of the log during the drilling of the hole for the dowel is prevented;

- drill a hole for the dowel. Moreover, the diameter of the drill is 3-5 mm less than the diameter of the dowel;

- the hole is drilled through 2-3 logs;

- the dowel is driven into the hole with a mallet. He must enter with effort. To simplify the installation of the dowel, it can be sharpened from below;

- the first dowel is set at a distance of at least 200 mm. from the edge of the log;

- all pins are recessed into the wood to a depth of 2-3 mm. Protruding fasteners will hang the logs; Material for the site www.site

- step of installing dowels in a log - 1-1.5 m.p. In the walls, the installation step changes and depends on its length. There should be at least two pins per log;

- installation is performed in a checkerboard pattern. In order not to go astray and install the fasteners correctly, the craftsmen advise marking the installation sites of the dowels with a pencil on the inside of the wall;

- installation displacement occurs on every fourth log;

- after fixing the log with a dowel, the safety nails are removed;

- after part of the logs are fastened with dowels, they are upset with a mallet so that they exactly take their seats. This helps to reduce shrinkage.

Vertical supports-columns

Installation of vertical elements (pillars, columns, racks) in wooden house performed by means of special devices (shrinkage compensators) - screw jacks.

- the log is cut in length minus 80-100 mm. By this amount, a house made of logs will shrink, and the jack can be lowered;

- a bowl is cut out at the bottom of the support;

- a jack is installed on top, which will compensate for the shrinkage of the house;

- the verticality of the installation is checked;

- the remaining vertical elements are installed in one line;

- the jack is adjustable in height.

Insulation of a log house

Thermal insulation can be divided into three stages:

1 - interventional insulation

Laying rolled heat-insulating material between the crowns of a log wall. The insulation sheet is laid in one layer, for reliability it is fastened with a stapler. The width of the canvas is 10-20 less than the width of the longitudinal groove. The amount of overlap is 50-70 mm. A meter before the end of the log (corner or opening), the insulation is laid in two layers. This is due to the fact that the log dries more intensively in the opening. The insulation is also placed in two layers in the bowls;

Laying rolled heat-insulating material between the crowns of a log wall. The insulation sheet is laid in one layer, for reliability it is fastened with a stapler. The width of the canvas is 10-20 less than the width of the longitudinal groove. The amount of overlap is 50-70 mm. A meter before the end of the log (corner or opening), the insulation is laid in two layers. This is due to the fact that the log dries more intensively in the opening. The insulation is also placed in two layers in the bowls;

2 - first caulk

It is carried out one year after the construction of the house. During this time, the most intense shrinkage occurs;

3 - subsequent caulking

Performed as necessary during the operation of the building.

When caulking, remember:

- only the outer walls are caulked;

- bowls are sure to caulk;

- a large amount of insulation can cause the crown to rise, which will make it necessary to raise the crowns of other walls.

Interfloor ceilings in a log house

As a rule, houses made of logs are one-story, but there are projects of two-story houses or houses with attics. In any case, during the construction process, there is a need between floors or between a floor and an attic, a basement.

The overlap is formed similarly to the lag wreath of the wall. Those. a support beam is cut into the log, on which the logs are laid, on which, in turn, the boards of the subfloor of the upper floor or attic will be laid.

Round logs are used for supporting beams, but glued beams are often preferred.

Of great importance for the strength of the structure is, which is determined by the width of the span and the distance between the beams. For calculation, you can use the table:

Note. A log or beam can be replaced with paired boards with a suitable width.

When installing intermediate floors, the tie-in is performed so that only 10% of the groove falls on the lower log, and the remaining one - on the upper log.

log house roof

A house made of round logs involves the construction of a massive roof, which will accelerate its shrinkage and create additional pressure on the logs of the walls. A massive roof involves the construction of a reliable roof truss system.

Features of mounting the truss system on a log house:

- install the rafter leg not on the upper log, but bring it inside the log. This will avoid blowing the joint;

- when mounting the rafter legs on the upper log, which performs the function of a Mauerlat, use sliding fasteners. Similarly, using sliding fasteners, mount the ridge run. This compensates for shrinkage;

- step of installation of rafter legs - 600-700 mm.;

- further installation is carried out in accordance with the requirements of the roofing material;

- the under-roof space is insulated without fail.

Installation of a warm circuit

The installation of window and door blocks is recommended to be carried out after shrinkage of the house from rounded logs. When installing, it is necessary to use casing bars. The bars are placed in a vertical groove, 50x50 mm in size, which is cut into the ends of the logs facing the openings. The task of the bar is to prevent the torsion of the log and compensate for the displacement of the block during shrinkage.

The window or door frame is attached only to the casing bar, but not to the end of the log. Galvanized nails or self-tapping screws are used as a fastener. The length of the hardware should not exceed the thickness of the box and the casing bar. A technological gap is left above the box, the value of which is 100-120 mm. (depends on the expected shrinkage value, which is determined by the moisture content of the log). The gap is filled with an elastic heat-insulating material.

The construction of a log house takes from 5 days to a couple of months, depending on the complexity of the project, the experience of the workers and the weather conditions for construction. A team of professionals is able to manage in a short time, and assembling with your own hands will take much more time.

However, regardless of the speed of construction, finishing work can begin only after the house has shrunk, i.e. about a year after finishing assembling the box at home.

Note. From the remnants of rounded logs, you can make sub furniture, benches or decor to decorate the site.

Shrinkage of the house from the rounded log

How to control the shrinkage of the log house:

- wait a year for primary shrinkage to occur;

- use jacks to adjust vertical elements;

- equip gaps over non-shrinking elements of the house: door and window openings;

- remember that walls can not only shrink, but also gain moisture, and, therefore, swell;

- take into account that the inner walls (piers) shrink faster than the outer ones, because they are more protected from external influences;

- slowly warm up the house, because in case of rapid heating, the inner walls will shrink quickly, and the outer ones will lag behind in this process;

- remember that the southern walls dry out faster, which means they shrink faster;

- control the shrinkage process of the log house and caulk the cracks in time.

Timber house decoration

Finishing works include: grinding, installation of low tide, installation of communications, external and internal decoration.

1 Grinding

The constructed wall must be sanded to a smooth surface. The production process of rounding involves obtaining a high quality surface of the log, but during the installation process, roughness may appear, which are best removed.

2 low tide

You can protect the log of the lower crown with the help of an ebb made of galvanized steel, plastic, copper, concrete, etc. The tide is installed in such a way that there are no gaps between it and the wood. If there are gaps, they are filled with sealant. The ebb is set at an angle relative to the wall surface and fixed with hardware.

3 Communications

It is possible to mount wiring and other communications only after shrinkage of the house. In this case, it is unacceptable to mount the wiring at the ends of the log, because. it can be deformed during the torsion of the log, which will lead to a short circuit. Installation of communications is carried out in accordance with the requirements of fire safety.

To install electrical wiring, users recommend using special overlays, and not cutting holes in the log, and thus not reducing its thermal insulation and load-bearing properties.

4 Exterior finish

Includes sanding logs, caulking cracks, finishing openings, etc. work.

5 Interior decoration

Includes all work that takes place indoors. This can be wall decoration with clapboard or drywall, installation of a finished floor, installation of stairs to the second floor, etc.

Construction of houses from logs - video

Timber house maintenance

In order for the house to retain its original appearance for a long time, you should take care of it on a regular basis, in particular:

- timely cover the log walls of the house with antiseptics. The frequency of application is determined by the manufacturer's recommendation;

- cover log walls with flame retardants;

- apply stain or lighten walls. Under the influence of ultraviolet light, the walls darken, and not always evenly. The use of various protective compounds allows the process to be slowed down, but the process cannot be stopped. Therefore, after the expiration of time, it will be necessary to cover the walls with a darker composition;

- paint the walls with glazing translucent paints, which, on the one hand, allow you to see the structure of the wood, and on the other, create additional protection;

- in extreme cases, sheathe the house outside with siding or clapboard. But, this is only if it is not possible to restore the wood.

Thanks to proper installation and maintenance, a house made of rounded logs will fully function for a long period and stand out among other buildings.

: where to start, what you need to pay attention to first of all when building a log house, how the construction ends.

Many developers before the start of construction there is excitement, a premonition of fuss and problems. Do not worry, anxiety happens to most, because it is not every year that you have to build your own house. Many build for the first time, once and for all. Without experience, it is difficult to remain calm and unruffled.

There are constant thoughts in my head: will they deceive me, will they follow the rules when building my house, will the house turn out to be solid and reliable, will there be enough money, etc.?

If you are building with a company "Chukhloma estate", then do not worry and be sure that your house from a bar will be built as it should, according to the Agreement. Chukhloma Estate has been on the construction market since 2001, during which time we have built so many wooden houses from logs and timber that we have lost count of them.

The main thing for us is building a house with high quality, so that our customers are satisfied with our work and continue cooperation in the future, recommend our company to their relatives, friends and acquaintances. And this is only possible if our customers are satisfied with our homes and our carpenters.

So, where does the construction of any house begin? That's right, from the base...

1. Building a foundation for a house from a bar

The construction of the foundation is the first stage in the construction of a house from a bar.

The most common types of foundations that are erected under timber houses are (MZLF), pile-grillage And pile screw foundation.

Of these three, the most sought after is pile screw foundation. Due to three factors: price, production speed and the possibility of its installation at any time of the year.

The pile-screw foundation has the lowest manufacturing price, compared to all the others, and this is the decisive factor in choosing it for most developers. Moreover, you do not need to wait for some time when it is ready. As a rule, one light day is enough to screw the piles into the ground. The next day, you can already begin to install the log house on it.

Since log houses are built year-round, the construction of other types of foundations is problematic, especially MZLF, because. concrete does not set well in the cold, and it is difficult for him to dig a trench in frozen soil.

Thus, if you want to build a house inexpensively, then pay attention to the pile-screw foundation. It has proven itself well in the areas of our customers. Houses made of timber and even logs, built by our company "Chukhlomskaya Usadba" 10 or more years ago, stand firmly on a pile-screw foundation, without any complaints from customers.

A foundation with a grillage is something between a pile-screw and tape in terms of price and manufacturing principle, so it is acceptable for those who do not dare to opt for the first and who have a fairly large house.

For those who decide to build thoroughly, to build a large house for several generations, it is worth stopping at a shallow strip foundation. This is the most expensive type of foundation, but also the most reliable. There is no doubt that he will stand under the house for the entire period of his service. Especially it fits the overall.

2. Types of timber, installation of a log house

After you have the foundation ready, the team of carpenters proceeds to the second stage of construction - the erection of a log house on it.

If the foundation is pile-screw, then before installing the house, a strapping row is installed on the pile-screw foundation, which will connect all the piles sticking out of the ground.

An ordinary bar with a section of at least 100x150 mm is used for piping: the larger the structure, the more rooms it contains, the more complex the foundation and the more piles, the thicker the bar should be.

The strapping row is necessarily processed, because. the timber is in contact with the metal, and this is not the best neighborhood for materials with opposite properties. Antiseptic strapping is a must!

In this article, we will consider the construction of a log house only from, which is a building material made of natural wood, made mechanically without the use of chemical action: a bar of natural moisture and chamber drying.

The first type of timber includes , and to the second dry profiled timber.

An ordinary beam differs from a profiled one in price - it is the cheapest and, therefore, affordable wooden building material due to the fact that it undergoes minimal processing.

During its manufacture, the wood layer is removed until a bar of the required section is obtained. Therefore, it is slightly rough to the touch, as it is customary to jokingly call it “shaggy timber” among carpenters.

A log cabin from a simple bar requires either additional processing of the walls in the form of a fence and grinding, or sheathing with other wall material.

Not only houses are built from ordinary timber, but also other types of buildings: utility blocks, garages, sheds, gazebos, it goes to the manufacture of a strapping row and to beam ceilings in floors and ceilings.

It has spikes and grooves on both sides, with which it closes in the wall when assembling a log house from it.

Both simple and profiled "raw" timber has a moisture content of 25-40%. The level of humidity depends on the period of manufacture and the environment, because wood is a hygroscopic material that has the ability to take and give moisture to environment. The longer the bar of natural moisture is in the open air, the drier it becomes.

Dry profiled timber- the most expensive type of wooden building material of all types of solid timber, since it undergoes additional drying in a heat chamber. Its humidity, according to GOST, should be 12-20%.

In appearance, it is no different from a profiled timber of natural moisture: it has the same grooves on two sides, smooth surfaces on the other two sides. A log house assembled from profiled timber does not require additional processing of the walls, because they are even, without roughness, have a beautiful texture pattern of wood. To preserve the integrity of the wood of the log house, the walls must be treated with an antiseptic and, if desired, given some shade.

A log cabin is being erected. Both types of locking in the corner keep heat well with high-quality workmanship, because. have a complex configuration that does not allow air to pass through from the outside.

A log house from a bar is built either under shrinkage or on a turnkey basis.

3. Construction of a house from a beam for shrinkage

The phased construction of a house from a bar implies that the construction of a structure for shrinkage or turnkey determines the further order of work.

The construction phase is longer in time, because the house is being built from a bar of natural moisture.

A house made of "raw" timber shrinks up to 10% in the first year of construction. This means that it will decrease in height, because. the beam in the rows will dry out, sit down. During this period, when the wooden building material will sag, windows and doors cannot be installed to avoid formation in the walls. Because window and door frames will prevent this, will keep the upper rows from sagging while the lower rows will shrink freely.

Thus, the upper crowns, which will be held by windows and doors, will not be able to tightly close with the lower ones and gaps will form between them. That is why they build a house from a bar of natural moisture for shrinkage, so that the rows of the house during shrinkage can tightly close, “grow” to each other.

To do this, after the construction of the log house, openings are made in those places where windows and doors will be installed so that there is ventilation inside the house.

The house is necessarily covered with a roof in order to protect it from precipitation, you can immediately make a capital roof, under the weight of which shrinkage will occur faster.

Shrinkage occurs for about six months, its most intense stage occurs in the first 3-4 months.

4. Construction of a house from a turnkey timber

A house is being built from chamber-drying timber, because it shrinks less, up to 3-5% in the first year of construction. With this construction option, windows and doors are installed immediately, but taking into account shrinkage, technological expansion gaps are made above them.

Compensation gap- this is the distance between the beam and the window or door frame, which gradually decreases during shrinkage. A heater is placed in the void of the gap and covered with cash on top. Over time, the beam will lie on the box, tightly pressing down the insulation with its weight, the distance between the window and the beam will disappear.

5. Roof installation

In order for the roof to be reliable, it would not be blown away even under the pressure of the strongest hurricane, it is necessary to observe a number of technological conditions during its construction.

First of all, it is necessary to provide a solid frame-rafter system: rafters - edged board 50x150 mm and crate - edged board 25x150 mm. The rafters are installed in increments of 0.6 m, the distance between the crate is 20-30 cm. These are optimal technological norms during the construction of the roof of a log house. They are suitable for all types of roofs.

The main types of roofs are gable, broken line(attic) and hip.

The most difficult to manufacture, because. the rafters on it are not solid, but with a break. Therefore, the construction of a sloping roof must be approached with special care so that it is sufficiently reliable. For its construction, only an experienced team of carpenters should be involved.

Good craftsmen with skills are also needed in the manufacture of other types of roofs, especially if a special roof window is being built.

6. Finishing a house from a bar after shrinkage

Finishing a house from a bar after shrinkage is the final stage in the construction of a house from a bar of natural moisture.

Six months later, the main shrinkage of the log house is already taking place, so you can proceed with the installation of windows and doors, interior and exterior decoration: laying the finishing floors and ceilings, installing stairs, wiring, etc.

It must be borne in mind that imperceptible shrinkage will occur even before a year, therefore, as in the case of building a house from a turnkey timber, the necessary compensation gaps are made above the windows and doors.

So, now you know the phased construction of a house from a bar, in what order it happens. Of course, this description is given in general terms, because for each stage of construction you can write a whole instruction on several sheets, since they all have their own characteristics, each has its own nuances.

But you have already learned the most important things, what you need to pay attention to in the first place.

The most important condition for the construction of quality wooden house- conscientious and skilled craftsmen. These are the people who work at the Chukhloma Usadba company.

Examples of the phased construction of a house from a timber for shrinkage with photos and videos:

Construction of a house from a bar under the project for shrinkage:

Construction of a house from a bar 6x9 according to the project for shrinkage:

The project of a house from a bar with a terrace

The project of a house from a bar with a terrace  Start of construction of a house from a beam for shrinkage according to the project "Committee" Start of construction of a house from a beam for shrinkage according to the project "Committee" |

Now you are ready to build your own wooden house. But it is worth being prepared not only financially, but also morally. After all, the construction of a wooden house is a very long, painstaking and time-consuming process.

The proverb can be attributed to the process of building a house: "Moscow was not built right away."

You should not even think that you paid the money and in a couple of months you have a beautiful house of your own. No, this will not happen.

The construction of a wooden house is carried out in several stages, which we will discuss in our article. We will try not only to highlight each of them, but to consider in more detail

First stage - Design

Designing a house is the first and one of the most important stages in the construction of a wooden house. After all, it is he who allows for all the nuances of future construction.

The project of your house can be both typical and individual. It all depends on your tastes and wishes.

The undeniable advantage of a typical project is that these ideas have already been implemented and tested. But there is also a minus - your house will not be individual in appearance.

But if you are driven by passion for the original, the solution is individual project. But even here you can’t do without a minus - work on such projects will take much more time than on typical ones.

Rule #1: Be very careful with your design. In the future, this will help you avoid unnecessary questions and costs.

The second stage - Logging for construction.

Wood harvesting is also very important point. The wood from which your house will be built must be of high quality and durable. And before choosing a developer company, you should pay attention to:

A. Own production or work through intermediaries;

B. How much the company spent in the construction market;

C. What guarantees are given;

There are many more factors, but we have listed those that are worth paying attention to in the first place.

Of course, we all understand that coming to any construction company, they will swear to us that the wood they use for construction is the best, the experience is huge and the guarantees are almost lifetime. From this "follows" -

Rule #2: Construction is best entrusted to a trusted company.

The third stage is the construction of the foundation.

The foundation is the basis of the house, so the issue of choosing a foundation should be taken seriously in autumn. To choose a reliable foundation, you need to know what kind of soil is on your site.

So you figured out the soil, chose the foundation. next moment- foundation construction technologies. Foundation pouring should only be done by professionals. And there should be no savings on concrete.

After pouring, the foundation must settle for 21 days.

Rule #3: No savings on concrete.

The fourth stage - Assembling the house.

The foundation has settled, and we begin to assemble the walls of the house. This stage of construction includes the installation of a log house with jute insulation, then the installation of floor and ceiling beams.

Rule #4: Check the material carefully when it arrives at the site.

Fifth stage - Creation of the truss system and roofing work.

The strength of the roof depends entirely on the supporting structure - the truss system.

When the rafter system is ready, they begin work on the crate.

Rule #5: This step should only be done by people with experience.

The sixth stage - Roofing.

In many ways, the roof determines appearance at home, but the main function is to protect the house from the penetration of precipitation and the elements.

Rule #6: Roofing materials must be of high quality.

The seventh stage - Shrinkage and shrinkage of the house.

The main works have been done: the foundation has been poured, the frame of the house has been assembled, the roof has been covered. It remains only to wait for the process of shrinkage and shrinkage.

Rule #7: The stage of shrinkage and shrinkage should take at least 6 months.

Eighth stage - Interior decoration of the house.

The main purpose of home decoration is to emphasize the individuality of the owner. It is at this stage that everything is in your hands. You can give free rein to your ideas.

The main purpose of home decoration is to emphasize the individuality of the owner. It is at this stage that everything is in your hands. You can give free rein to your ideas.

BUT: before finishing the house, you need to caulk it.

Our wishes: Take the construction of your house very seriously, do not rush, then, when fully prepared, it will pleasantly surprise you.

September 1, 2017Specialization: facade finishing, interior finishing, construction of dachas, garages. The experience of an amateur gardener and horticulturist. He also has experience repairing cars and motorcycles. Hobbies: playing the guitar and much more, for which there is not enough time :)

Construction technology

The process of building a log house can be divided into five main stages:

Stage 1: project preparation

The design of the log house does not, in fact, contain any nuances. At this stage, as with the construction of any other house, you need to clearly imagine what the building will be, and then draw it on paper.

If you can’t decide on a layout, take as a basis finished projects houses on our portal.

When the dimensions and layout of the future house are known, you need to decide on the type of roof. From myself I can recommend building a mansard roof. This will allow you to expand the useful area of the house by at least one and a half times with virtually no increase in the cost of its construction.

When the project is ready, count the amount of materials and draw up a diagram.

Stage 2: which log to use

Before purchasing materials, beginners are usually tormented by the question - from which log is it better to build a house, rounded or chopped? The rounded log has an exact shape and diameter, in addition, there is a groove in the lower part, which simplifies the stacking of logs and prevents the formation of gaps between the crowns.

A chopped or debarked log has a bottom layer of bark. Thanks to the resin that covers it, it is more resistant to moisture and decay. But on the other hand, the shape of such a log is less even, which somewhat complicates the construction. So does it make sense to build a house from chopped logs?

It's up to you, of course. The only thing I note is that at present there are all kinds of protective impregnations that make any wood moisture resistant and resistant to negative biological influences.

Keep in mind that in addition to logs, you will need other materials to build walls:

- Nagels for connecting the crowns of the house to each other;

- Mezhventsovy heat-insulating material.

Stage 3: building the foundation

The construction of a strip foundation usually takes about a third of the total budget allocated for the construction of a house. Besides, strip foundation takes at least a month, or even more. Since wooden housing is lightweight, in most cases it is more expedient to build a columnar foundation.

Its principle is to build block or brick columns on a sand and gravel cushion. The distance between the posts, which are installed in rows, is one and a half to two meters. From above, all columns are connected with a grillage (beams).

For unstable soils and uneven areas, it is better to use a pile-screw foundation. The principle of its device is even simpler - metal piles-drills are screwed into the ground, which are connected from above with beams.

The price of these foundations is an order of magnitude less than the strip foundation. However, they have one significant drawback - they do not allow a basement or cellar to be built under the house. Therefore, for the construction of an underground room, you still have to make a strip foundation.

Regardless of what kind of foundation you build, be sure to waterproof it horizontally to protect the walls from moisture.

Stage 4: building walls

After preparing the foundation, we proceed to the main stage - the construction of the walls of the log house. The instruction looks like this:

| Illustrations | Description of actions |

|

Laying the first crown:

|

|

Laying subsequent crowns:

Thus, install dowels in transverse and longitudinal logs through a row.

|

|

Hole cutting:

|

This completes the construction of the walls.

Stage 5: building a roof

Now you need to lay the floors and install the roof. Work should begin with the pediments, which are built from a log "pyramid" according to the same principle as the walls. To connect them and give the structure rigidity, several runs should be used.

Further work is performed in the standard way, i.e. just like building any other house.

Output

We figured out the main points of building a log house, otherwise you should not have any problems. The only thing I recommend is to additionally watch the video in this article. If you did not find the answer to any of your questions, leave it in the comments, and I will be happy to answer you.

September 1, 2017If you want to express gratitude, add a clarification or objection, ask the author something - add a comment or say thanks!